Part 2: Seeing the forest from the trees: Reducing EPD myopia - Dec blog post

As the need to reduce carbon emissions becomes more acute, design teams must focus on reducing embodied carbon in their buildings. In last month’s blog, we identified the biggest drivers, including the decision to build in and of itself, as well as building size, extending service life and then reducing the largest impacts due to structural concrete and steel. The drive to reduce embodied carbon is also leading architects to request environmental product declarations (EPDs) for insulating glass. But are insulating glass EPDs important for design decision making?

This month, I am joined again by my colleague, Alexandra Blakeslee, to explore how to approach carbon emissions-focused design decisions for glass, and especially how to use (or not) EPDs in this product category. We conclude that using EPDs for insulating glass sourcing decisions is largely irrelevant. The most important factors are in the architectural design decisions, such as insulating glass make-up and lifespan, not where the glass comes from.

The Big Picture

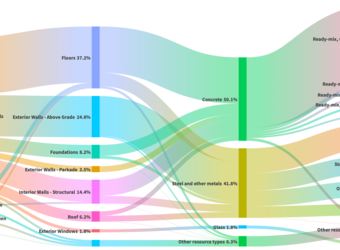

A recent lifecycle assessment of an office building conducted by Anthony Pak of Priopta Innovations Inc. reveals that glass makes up less than 2% of the embodied carbon of a building. Structural elements, such as concrete and steel/iron, comprised 50% and 35%, respectively. The majority of the 6.9% contributed by aluminum is attributed to the curtainwall. Pak states, “Glass is not particularly carbon intensive, but the materials used for framing it can drive emissions up.”

Of course, the actual impact in each building depends on the window-to-wall ratio, and the building size and massing, but this gives us a sense its magnitude.

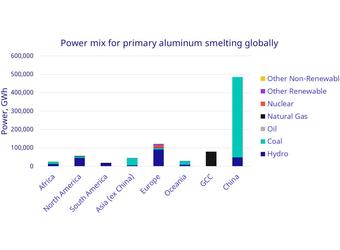

Pak reinforced what we have said previously: Aluminum production, while energy intensive, doesn’t have to be as carbon intensive, if it is made from renewable electricity sources or if recycled aluminum is used...to continue reading click here.

(the full blog, as well as previous posts, are hosted on usglassmag.com)