Specific solutions for windows, doors, and facades

Innovating to overcome particular challenges

Sometimes, markets and applications call for very particular solutions. We are passionate about problem solving, and put our minds to even the most specific of challenges to deliver you the quality you expect in the form that you need it. Whether that is complying with particular regulatory requirements, innovations to overcome temperature phenomena, or devising methods for complex application, we engage with you to isolate and address the challenge at hand.

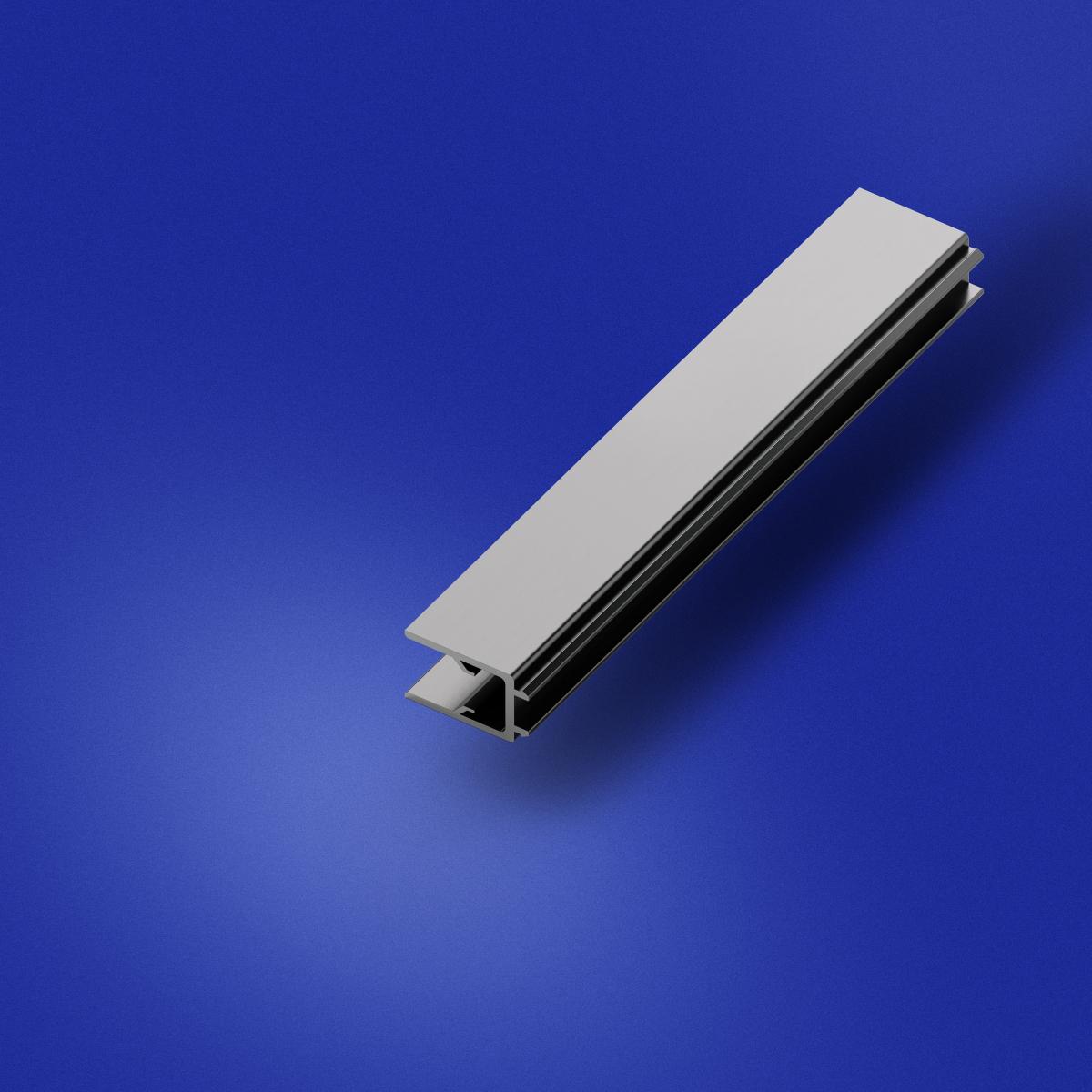

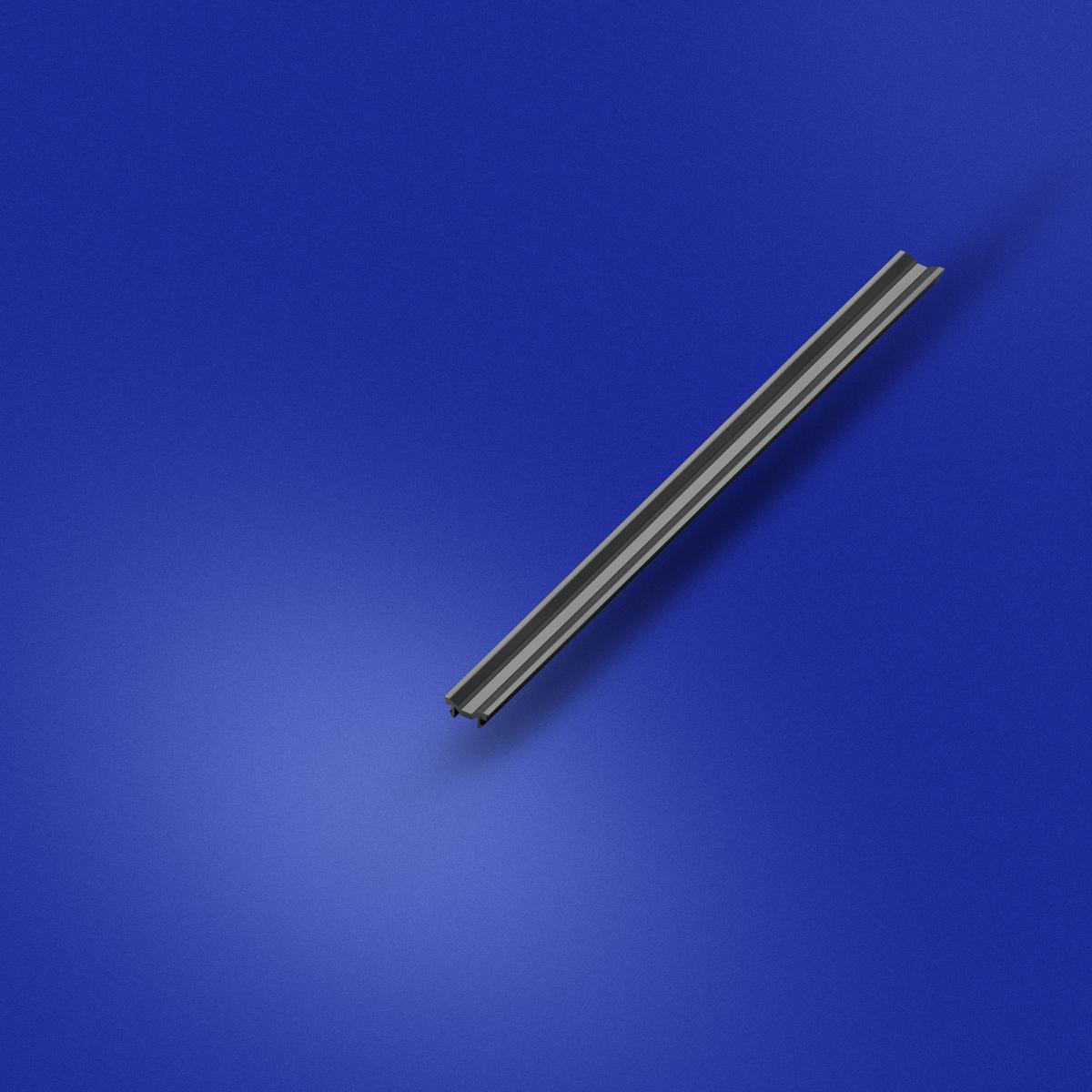

Anti bi-metal

The so-called bi-metallic effect occurs when there is a large difference in temperature between the inner and outer frame of a door (e.g. through intense sunlight). The outer frame expands and can cause distortion of the door and locking difficulties. Our solution allows the outer frame to expand without affect the fit of the inner frame, meaning it continues function as normal. Easily replaced, this addition comes pre-installed, meaning there is no change to the process on your side.

Drainage

French NF P24-301 regulation stipulates that windows must have drainage holes for water to filter through the profiles. By supplying profiles with drainage holes means that fabricators do not need to drill these holes themselves, thereby adding value to the product they sell.

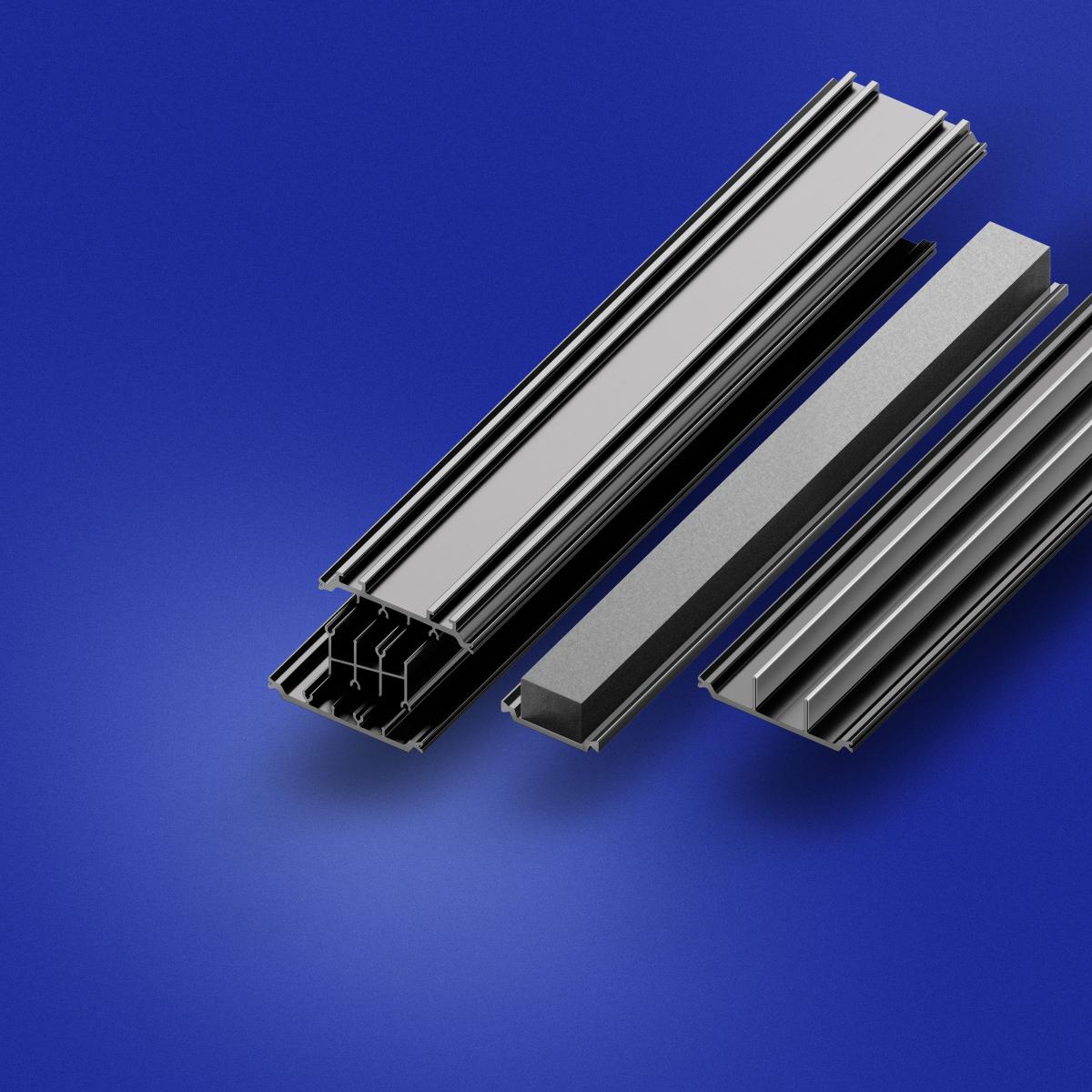

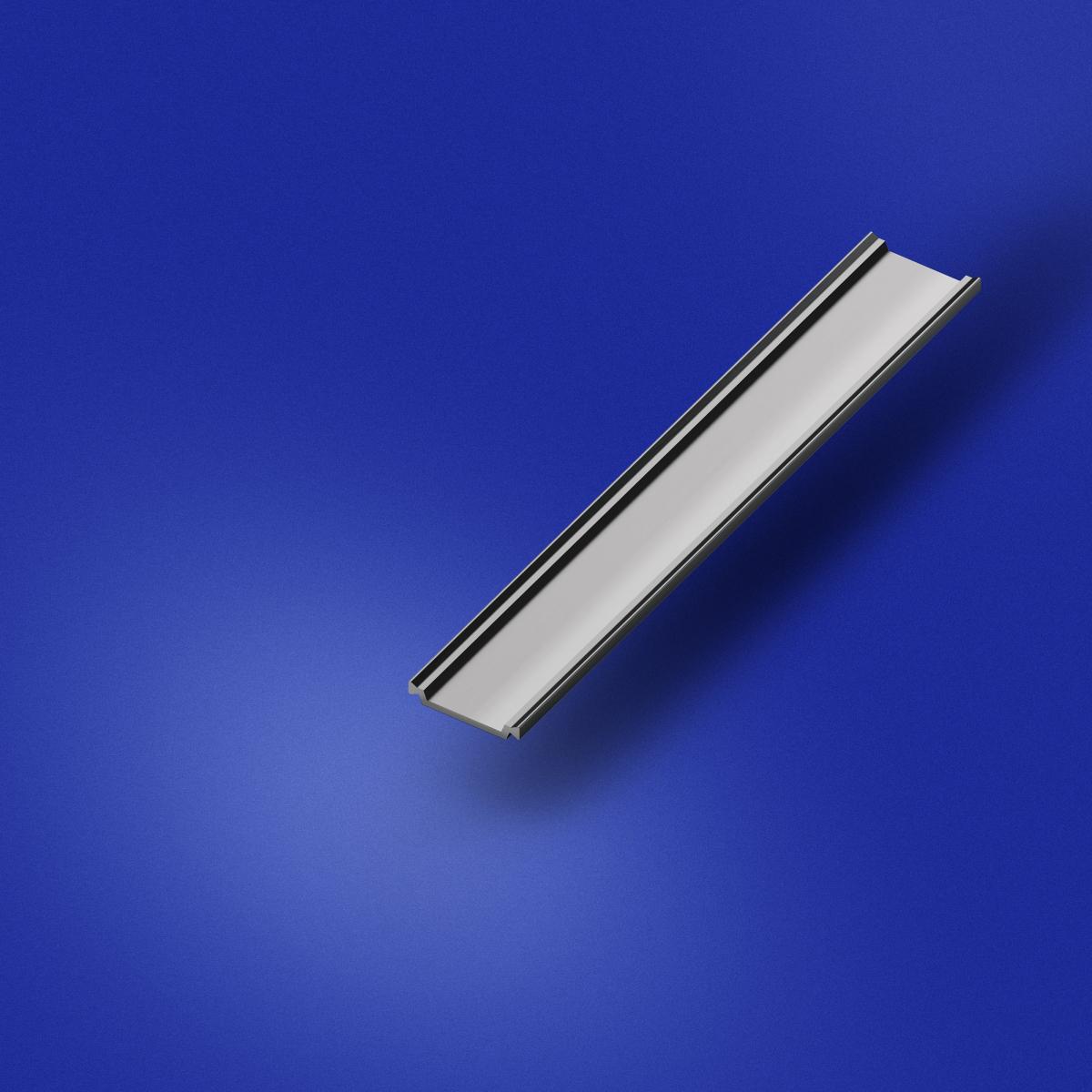

Solutions for sliding windows and doors

Sliding windows and doors are a common choice in modern buildings placing emphasis on a balance between aesthetics and functionality. Preserving thermal optimization whilst maximizing visual minimalism and mechanical functionality is a complex challenge. In order to achieve this, our profiles are produced to tight tolerances with exact contours and geometry, and also have an optimally smooth surface to allow friction-free movement. We have several different profiles for sliding windows and doors in our standard profiles catalogue.

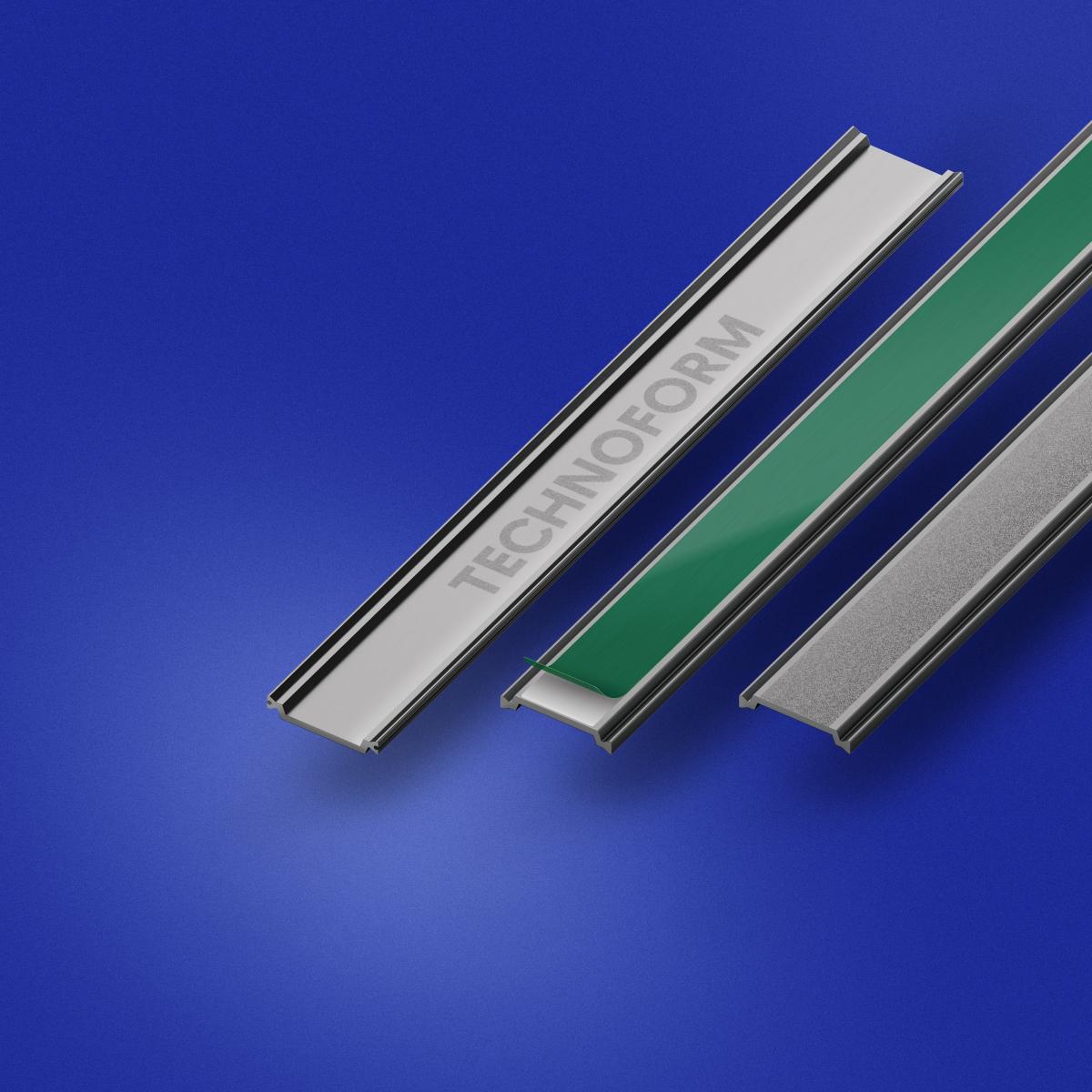

Adhesion prime

Bonding components to aluminum windows with thermal break is one of the most challenging processes. Our solution improves adhesion to the polyamide surface, resulting in an excellent and certified bond between the adhesive and the substrate.

Adhesion Prime works thanks to a patented technology consisting of a dispersion and mechanical connection of aluminum powder particles and their oxides to the polyamide surface. Technoform Polyamide strips with APR are the only certified substrate for structural bonding available on the market.

This unique Technoform technology allows a strong bond between the adhesive and the substrate, while maintaining the same thermal conductivity of a regular Technoform polyamide.

Adhesion Prime solution is intended for use in window, door and façade designs that require adhesion between the thermal break and the frame, panel, or glazing. This ASTM certified solution allows for regular, weather resistant and structural bonding.

Coating prime

Coating Prime is the confection that increases the range, in terms of moisture, of good paintability of the polyamide thermal break profile, improving painting powders adhesion and reducing blistering.

Coating Prime product consists of a dispersion of particles of aluminum powder and its oxides on the polyamide surface, optimizing the deposition of the powder paint while maintaining the low thermal conductivity of the polyamide.

Better adhesion of the powder paint to polyamide.

Better attraction of the powder paint on the polyamide, coating even less visible areas.

Minimization of blistering that may appear during the coating process.