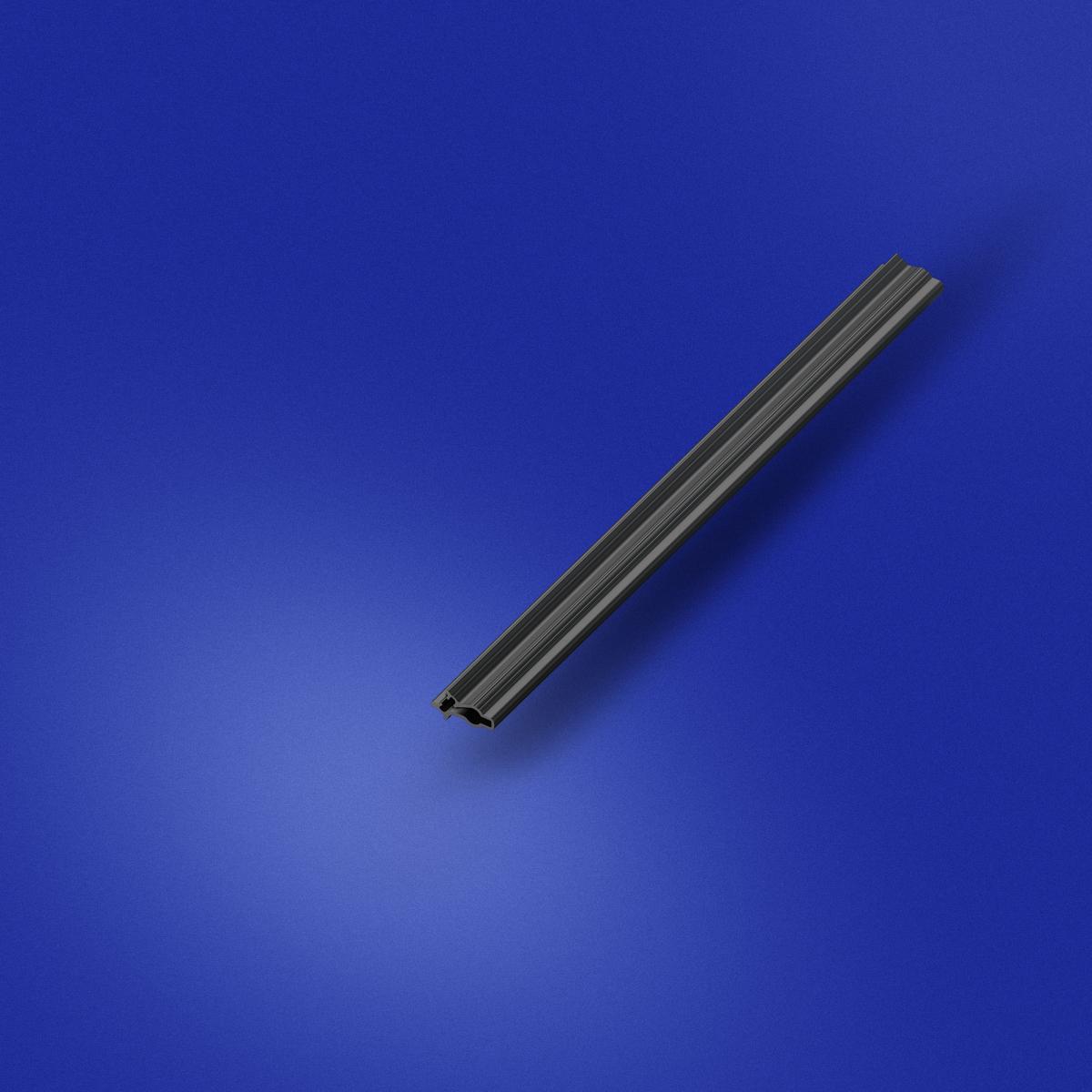

Slide profile for forklift attachments

Heavy-duty profiles

Let us do the heavy lifting

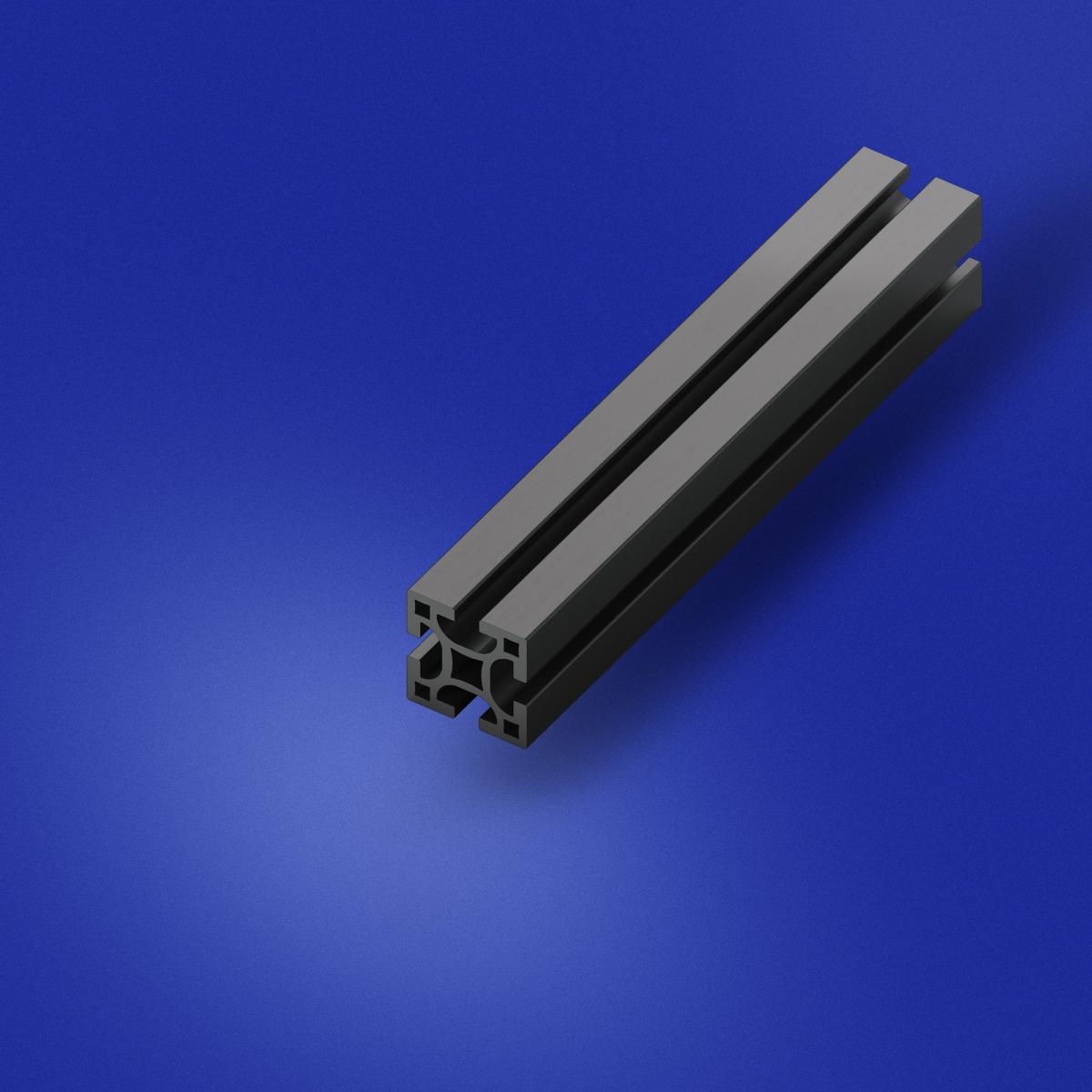

To help carry heavy goods, forklift trucks are equipped with a mast with a slide profile to anchor the two cantilevered arms (forks) that bear the load. The material used for this purpose must have high mechanical resilience to sustain the weight, and be well lubricated to counteract high levels of abrasion between metal components. This lubricant collects dust and metal pieces, therefore needing to be frequently replaced; this becomes both expensive and time consuming.

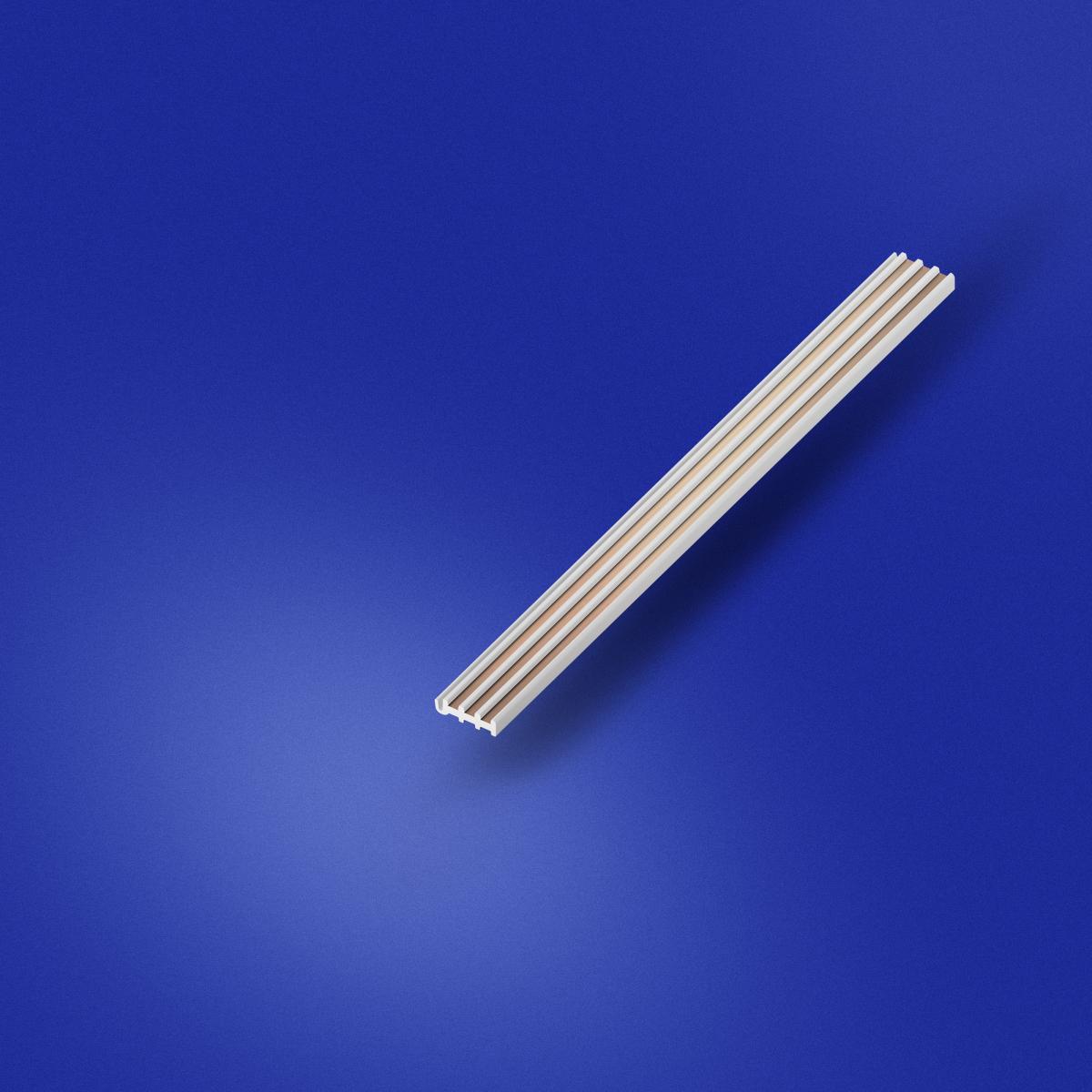

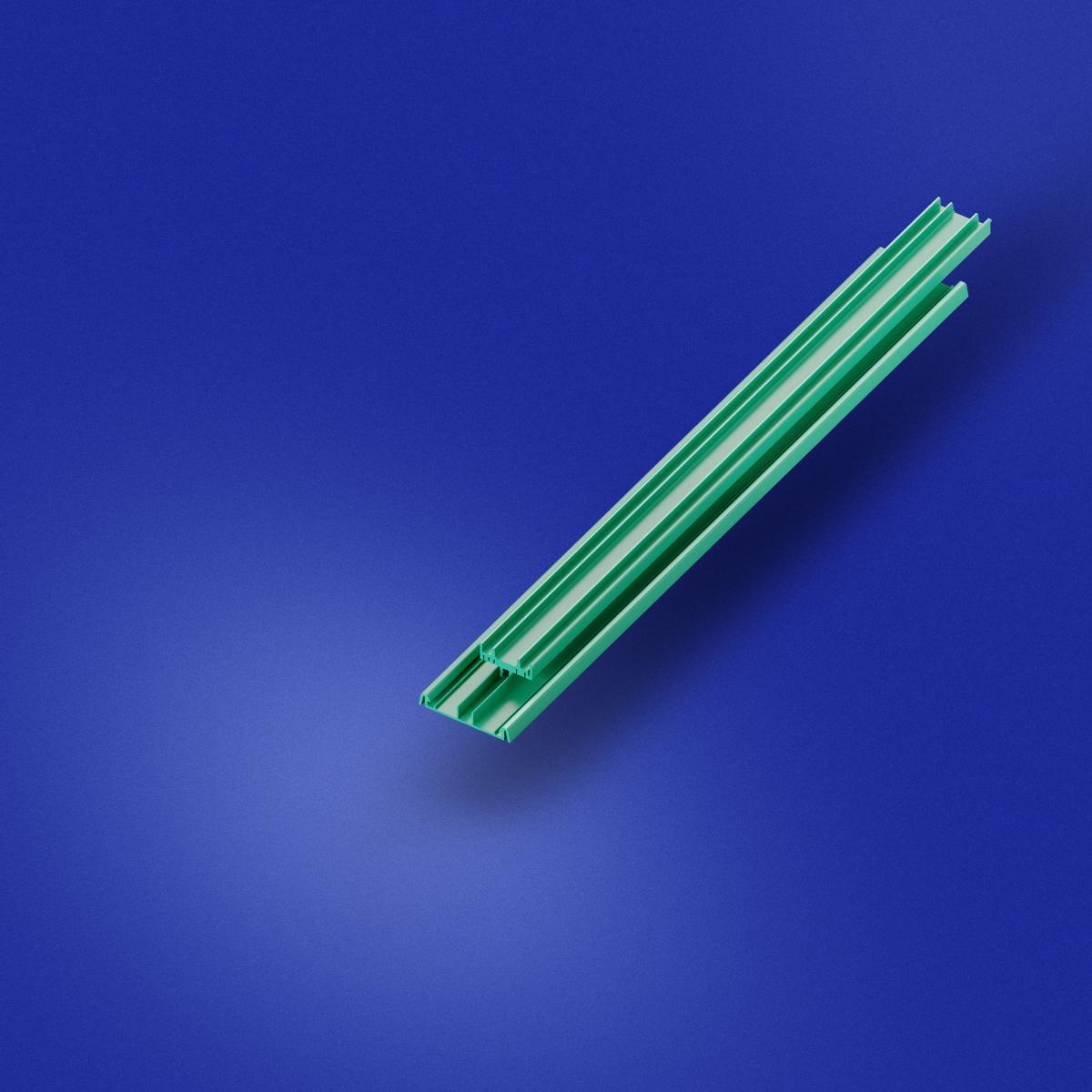

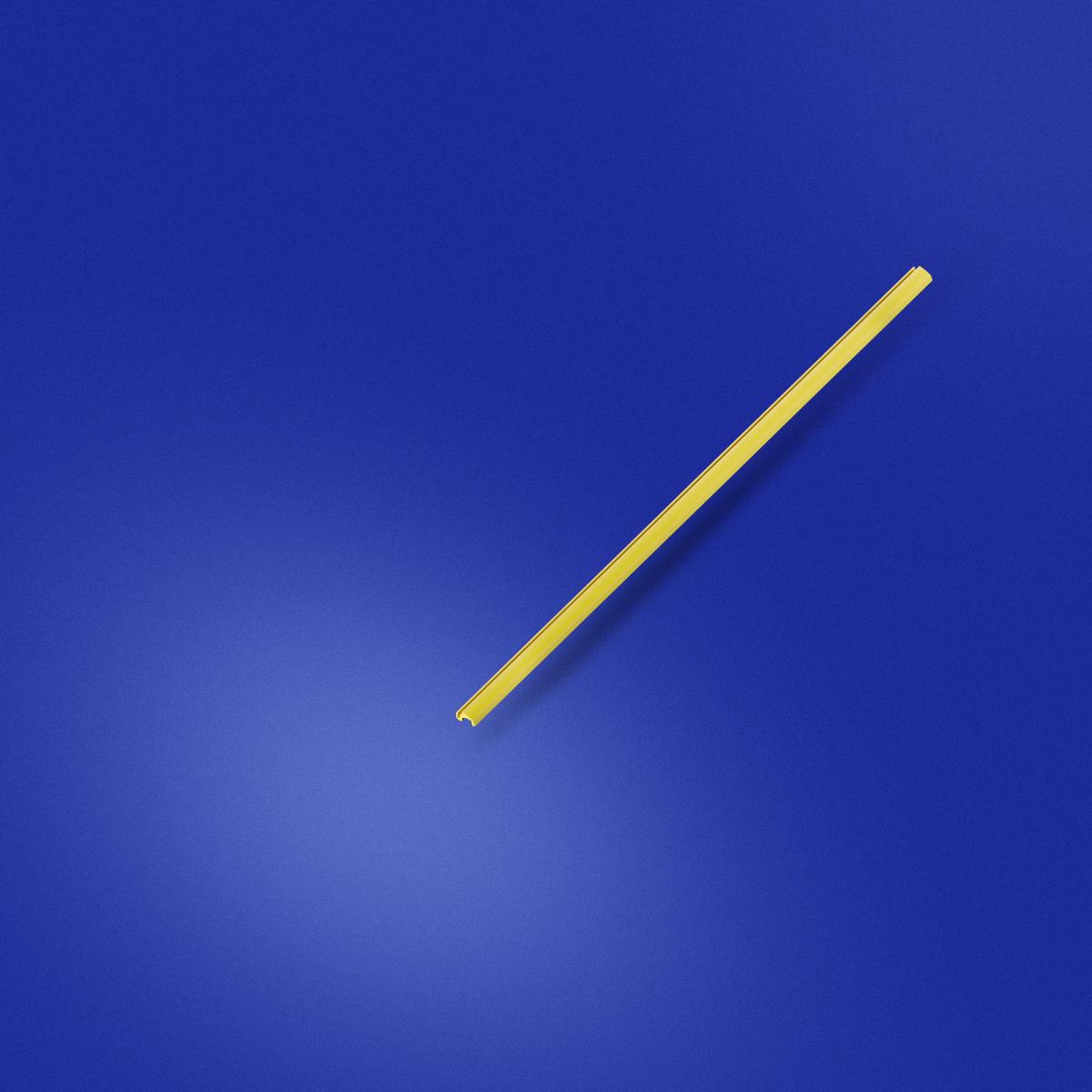

Our hard-wearing plastic profiles are extruded with incredibly smooth surfaces thanks to our special extrusion process. Made from modified materials with sliding additives, they deliver optimal sliding properties without the need for additional lubricants. This means less time spent on maintenance and more time in operation to help lighten the load.

Plastic profiles optimize forklift attachment systems

Our slide rails made of glass fibre-reinforced polyamide are significantly lighter than metal and have high gliding properties and strength.

Despite high filling levels, we achieve very smooth surfaces and precise contours. This means that metal can be substituted without any functional restrictions. Thanks to weight savings, plastic achieves a reduction in the CO2 footprint.

Advantages:

• Silent, lubricant-free gliding

• Lightweight and robust

• Simple assembly and disassembly

• Increase sustainability and reduced energy costs

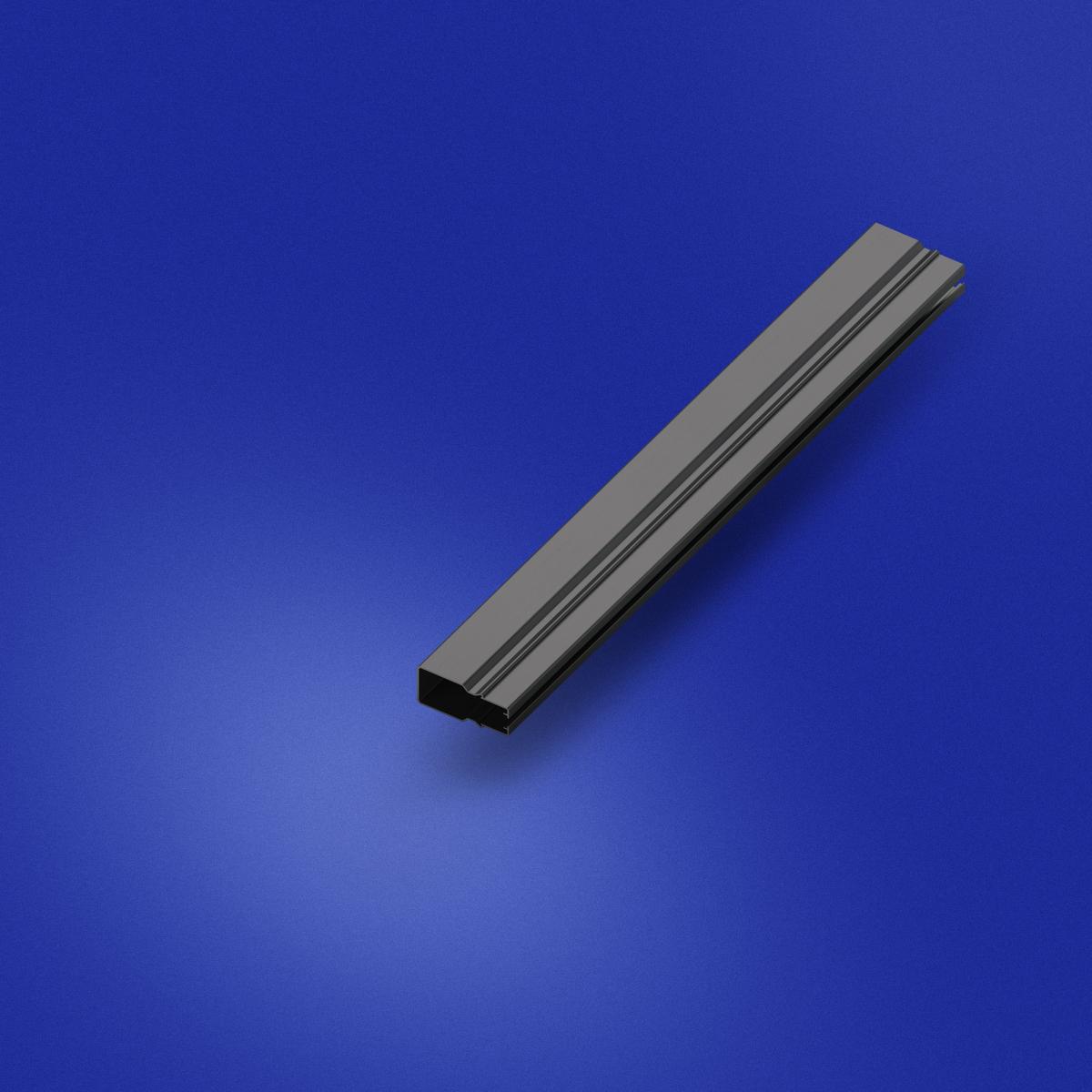

Reference project: Brass replacement

Thermoplastics are a substitute for metal and make it easier to fit forklift attachments manufactured by KAUP GmbH & Co. KG. Thermoplastics and fibre-reinforced plastics are a viable alternative to conventional materials. Together with the leading manufacturer of forklift truck attachments, Technoform launched a pilot test.