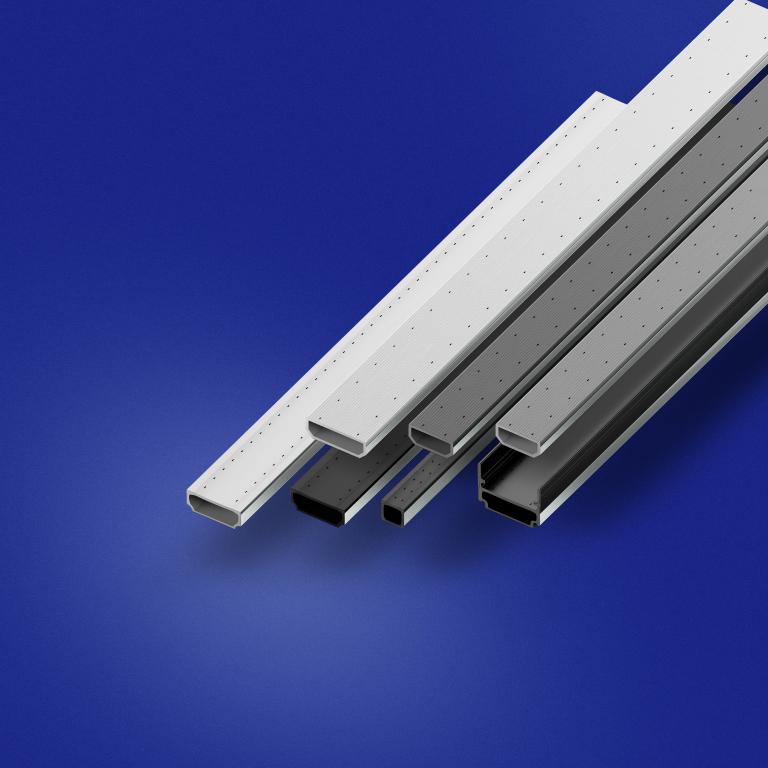

Thermally optimized warm edge spacers

High energy efficiency, long service life, and indoor comfort are key factors to sustainable building design. High-performance fenestration is a key component of delivering a comfortable and energy efficient built environment. To achieve this, a durable, thermally optimized edge bond for insulating glass is required. This is provided by our warm edge technology.

Warm edge spacers work by separating the panes of glass in double or triple glazing and are made from low conductivity materials. The cavity created by the spacer reduces heat transfer across the center of glass, and the use of a warm edge spacer reduces thermal conduction across the opaque area at the edge of glass. By reducing heat transfer at the edge bond, use of warm edge spacer translates into energy savings for buildings no matter what the season.

In every climate, their use improves thermal comfort for occupants by keeping the room-side surfaces of the window closer to room temperature. In cold weather, this has the added benefit of reducing the risk of condensation and subsequent mold growth, and also reducing uncomfortable downdrafts.

Our warm-edge solutions set new standards in surface quality and match the highest requirements of architects and building owners. Our hybrid warm edge spacers achieve excellent thermal performance without sacrificing design and, most importantly, durability.

Contact us if you want to increase the quality and durability of your insulating glass through an optimized insulating glass edge bond.

Hybrid warm edge spacers

Our hybrid warm edge spacers come with a proven twenty-year track record and are designed to meet the many requirements of today’s insulating glass systems. These spacers are considered hybrid because they are made from a combination of precision engineered polypropylene and ultra-thin stainless steel. The stainless steel section of the spacer, which wraps around its sides and back, gives the same durability and processability benefits as metal box spacers: zero moisture-vapor and gas transmission through the back of the spacer, and the ability to be processed on conventional bending equipment. The presence of specially engineered polypropylene bridging the top significantly reduces its thermal conductivity. As a result, our range of hybrid spacers achieves the warm edge performance of non-metal spacers, while maintaining the benchmark durability of stainless steel box spacer.

Our unique extrusion process allows us to customize our spacer designs to your needs, whether you are starting your transition to warm edge or need the highest thermal performance in insulating glass. Designers also love the aesthetics of our hybrid warm edge spacers because of the attractive surface finish and range of available colors. Our hybrid warm edge spacers are used across the full range of fabrication processes such as bending and cut and corner. The flexibility of the spacer also makes it a go-to for radius shaped IGUs, such as arch-tops and circular shapes, and for bent/curved insulating glass units.

Designed for small spaces

This hybrid warm edge spacer is ideal for thin insulating glass units used in retrofits on historic buildings where a smaller thickness of insulating glass must be maintained. It can also be used for triple glazing, when high thermal performance is needed, but the overall unit thickness is constrained. It complies with EN 1279-2, 3 & 6, DTA and ASTM E2190.

SP12

- Ideal for small cavities where an air space of less than 10 mm is needed

- Ability to maintain existing building aesthetics while increasing thermal performance

- Flexible for creating bent/curved glass and tight radii for arch-tops and circular units

Equipped for every challenge

These hybrid warm edge spacers are our best-selling spacers because they can be used in almost any application: In commercial or residential fenestration and using a wide range of sealant types. They comply with the requirements of EN 1279-2, 3, & 6, DTA, and ASTM E2190. They are also certified as Passive House Component Class phB for Cool, Temperate climate.

SP13

- Flexible for creating bent/curved glass and tight radii for arch-tops and circular units

- Excellent choice for small to medium-sized units

SP14

- Higher rigidity provided by patented steel stiffening wires

- Ideal for larger insulating glass sizes where more rigidity is required

Optimized for improved processing

Innovation is one of our key principles at Technoform, which has led to our enhanced hybrid warm edge spacers for even better processing and handling. Building on our warm edge technology, we designed these spacers with more rigidity in mind, making it even easier to process and handle the spacer frame, especially for large sizes. Each of these spacers have specific features that increase productivity for insulating glass manufacturers while maintaining the thermal performance and durability we are known for.

SP17

- Increased 8mm height and patented steel wires improves rigidity

- Drop-in replacement for 8mm tall aluminum or stainless-steel spacers

- Highest desiccant capacity and longest primary seal length for best-in-class durability

- Ideally suited for even larger units

- It complies with the requirements of ASTM E2190

SP18

- Like SP14, but the use of a larger wire diameter improves rigidity even further

- Reduces scrap during processing

- Ideally suited for even larger units

- It complies with the requirements of EN 1279-2, 3, 4 and 6, DTA, and the RAL quality and test regulations. It is certified by Cekal and CSTB.

Designed as a first step to warm edge

Start your transition from aluminum with this beginner hybrid warm edge spacer. This spacer is perfect for making the transition to thermally optimized edge bonds. Using a more basic steel grade than our other hybrid spacers allows some ductility for shapes, offers mid-range thermal performance, while still preventing moisture-vapor and gas transmission due to the hybrid’s signature solid metal back. It complies with the requirements of EN 1279-2, 3, and 4.

SP19

- Mid-range conductivity of 0.50 W/mK (lambda-equivalent) as a first step to warm edge

- For cut and corner fabrication

- Ability to create small-range curvatures with radii greater than 85 cm

Cold-bendable solution for highest thermal requirements

The SP24 combines excellent thermal conductivity and low lambda equivalent values with the advantage of cold bending for maximum productivity, similar to a standard warm edge spacer. To achieve this excellent value, a multilayer barrier foil for thermal separation has been integrated into the geometry of the spacer profile. Targeted bending points in the profile ensure optimal corner formation and reduce stress on the foil. It can be cold-bent on existing equipment, thus doubling the production speed compared to warm bending - without additional investments in new bending machines and tools. Therefore, switching is very easy and cost-effective.

SP24

- Cold-bendable

- Low conductivity of 0.22 W/mK (lambda-equivalent)

- Increased productivity compared to warm bending

- Easy integration with existing machinery

- Maximum process reliability and reduced waste

- No limitation in frame sizes

- Meets the requirements of EN 1279 Part 2, 3 & 6 with PU & PS and EN 1279-4, appendix C, H

Improved sightline aesthetics in structural glazing applications

The latest addition to Technoform’s family of hybrid warm edge spacers is designed for use in structural silicone glazing (SSG) applications. The addition of a matte black finish to the spacer’s steel sidewalls reduces the risk of unwanted glare from shiny metal surfaces which can sometimes be seen along the sightline of an insulating glass unit.

SP25

- Matte black pinstripe on sidewalls

- Resistant to scratching and chipping

- Consistent with PIB black color

- Like SP14, rigidity is provided by patented steel stiffening wires

- Same great thermal performance as Technoform‘s other hybrid warm edge spacers

- Surpasses the durability requirements of ASTM E2190 with a dual seal PIB/silicone sealant system. The Insulating Glass Certification Council (IGCC) lists this product as an approved spacer in the plastic hybrid stainless steel (PHSS) classification.