Thermoplastic construction profiles

High functionality

Lightweight and corrosion-free

Customizable solutions

Construction profiles that are built to last

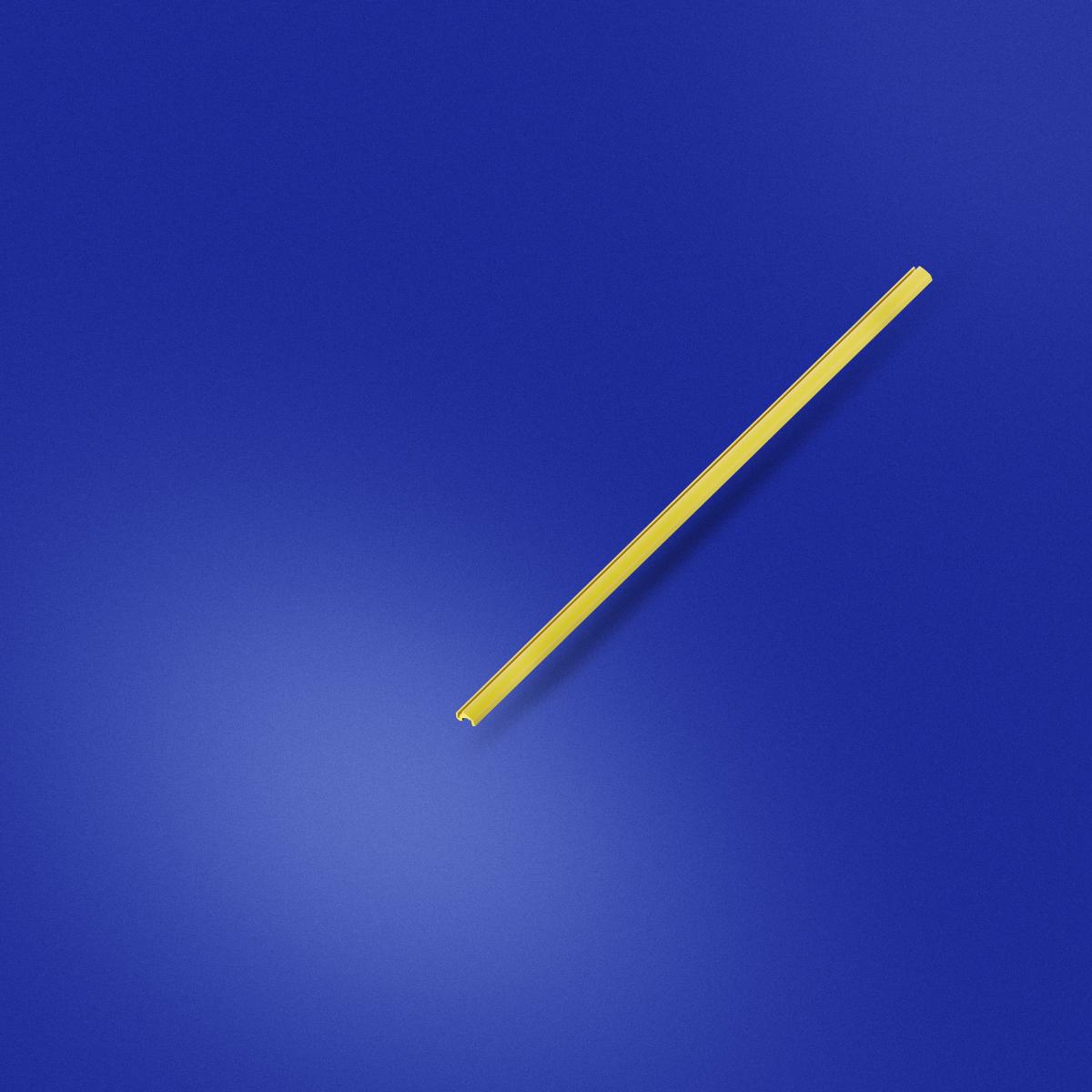

System modules can allow for easy construction and assembly of production facilities, workshop furniture or other functional equipment components. Typically made of aluminum, these construction profiles feature slots and connecting pieces to assemble a three-dimensional element. Nonetheless, the use of aluminum poses certain challenges. Often, there is a lack of electrical insulation and interference occurs due to electromagnetic radiation. Moreover, the system may be prone to corrosion or simply too heavy.

Thermoplastic profiles offer comparable performance with the added advantage of being lightweight, electrically insulating and non-corrosive. They have excellent sliding properties, can be produced with antiseptic qualities, and offer a lower level of heat transfer. What's more, they can even be tailored to your individual color scheme with an endless range of colors—rather than having to paint metal profiles, the plastic itself is colored, reducing the appearance of wear and scratches.

Plastic profiles can be used to supplement existing system modules, either adding to or ultimately replacing aluminum components. Their contour accuracy and tolerance range matches that of standard construction profiles.